Marine Engine Technology

There’s something fascinating about the way engines bring vessels to life. From small fishing boats to massive container ships, marine engines are the silent giants pushing ships across oceans, rivers, and harbors. Without them, maritime trade, fishing industries, and naval defense would grind to a halt. If you’ve ever wondered what really makes a ship move or why marine engines differ from car engines, you’re in the right place.

I still remember my first encounter with a marine engine, it was aboard a training vessel during a student field trip. The engine room was loud, hot, and oddly mesmerizing. Rows of pistons and crankshafts worked in perfect rhythm, like an orchestra hidden beneath the deck. That experience left me with a lasting curiosity about how these machines actually function and why they’re built the way they are.

This article will walk you through the basics of marine engine technology. You’ll learn what these engines are, how they evolved, and why they’re so important to the global economy. By the end, you’ll not only understand the essential parts and functions but also see the bigger picture of how marine engineering ties into trade, sustainability, and even future innovations.

So, let’s dive in, no pun intended, and explore the nuts and bolts of marine engines, starting with the basics: what they are, why they matter, and how they’ve developed over time.

What is Basic Marine Engine Technology?

At its core, basic marine engine technology refers to the study and application of mechanical systems that power vessels on water. These engines are not just scaled-up versions of car or truck engines. They’re specially designed to handle long voyages, harsh marine environments, and heavy-duty tasks.

Unlike automotive engines that focus on speed and efficiency for short distances, marine engines are built for endurance and reliability. They need to push massive loads, sometimes thousands of tons, across long distances while consuming fuel as efficiently as possible.

Marine engines are broadly divided into two categories:

- Main propulsion engines – the primary source of power that drives the propeller.

- Auxiliary engines – smaller engines that generate electricity and support onboard systems like lighting, refrigeration, and navigation.

Understanding the basics of these engines gives us a foundation to appreciate the technology behind every ship that sails the seas.

Importance of Marine Engines in Modern Life

It’s easy to overlook marine engines if you’ve never stepped inside an engine room, but their impact on daily life is enormous. Around 90% of global trade moves by sea, according to international shipping statistics. Every container of electronics, every barrel of crude oil, and every ton of grain transported overseas depends on marine engines working day and night.

Beyond trade, marine engines support industries like fishing, tourism, and defense. Think of ferries transporting commuters, cruise liners carrying thousands of passengers, or naval ships securing coastlines,all rely on dependable engine technology.

The importance of marine engines extends even further into environmental and economic considerations. Fuel consumption, emissions, and engine efficiency are directly tied to global sustainability goals. Innovations in basic marine engine technology, such as dual-fuel systems and hybrid designs, are shaping the future of green shipping.

Simply put, without marine engines, the world would be far less connected, and modern economies would struggle to function.

A Brief History of Marine Engine Technology

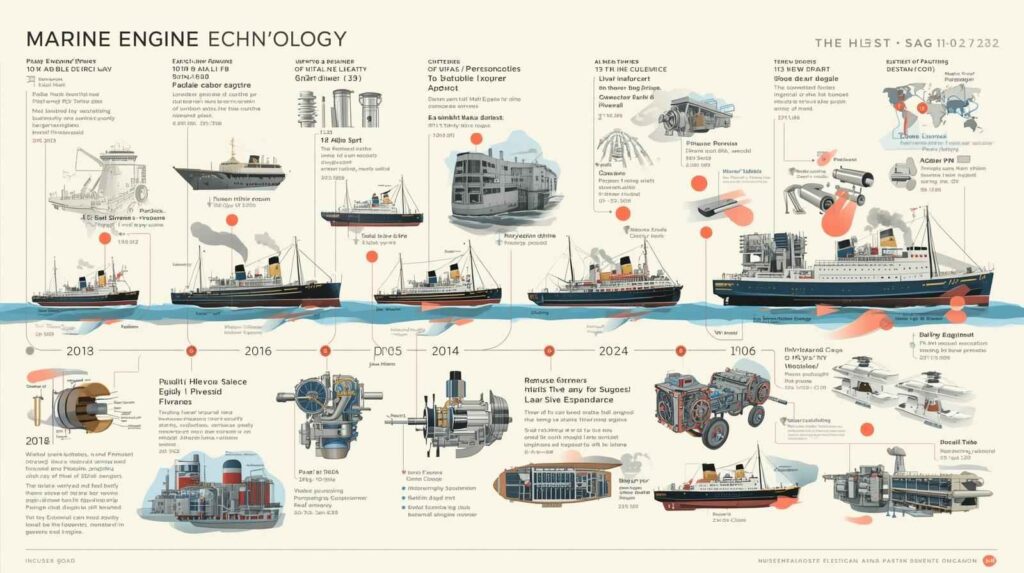

The story of marine engines goes back to the Industrial Revolution. Before engines, ships relied solely on sails and manpower. While effective, wind-powered vessels were slow, unpredictable, and limited by weather conditions.

In the early 19th century, the advent of the steam engine changed everything. Paddle steamers became the first powered ships, revolutionizing transport along rivers and coastal waters. Later, triple-expansion steam engines improved efficiency and made long-distance travel more practical.

By the 20th century, diesel engines began replacing steam engines due to their greater efficiency, reliability, and power. Diesel engines remain the backbone of modern marine propulsion, powering everything from tugboats to supertankers.

Today, the evolution continues with gas turbines, LNG-fueled engines, and hybrid-electric systems being developed to meet stricter emission standards and rising energy demands. The journey from sail to steam, then to diesel and beyond, highlights the constant innovation driving marine technology forward.

Core Components of Marine Engines

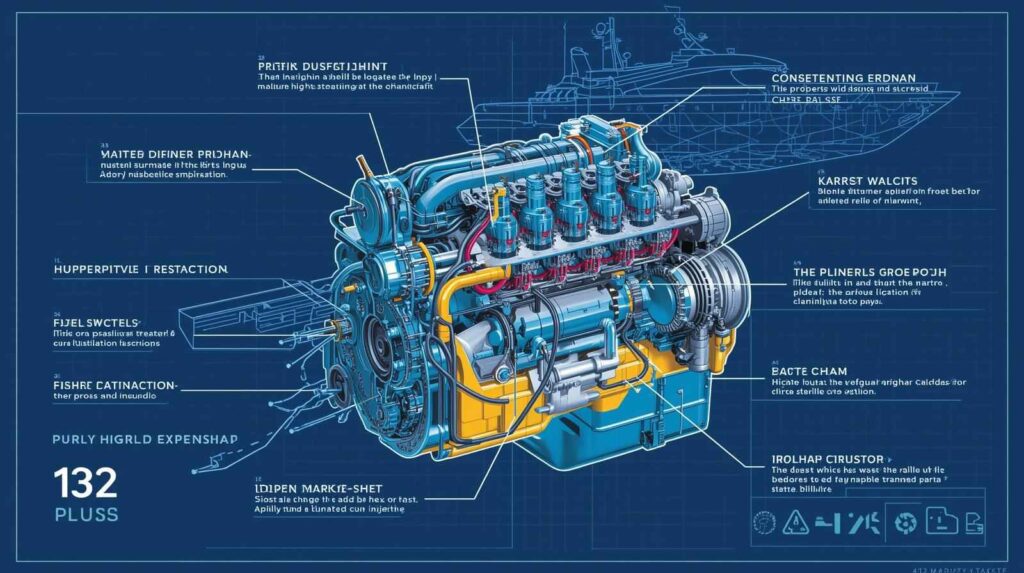

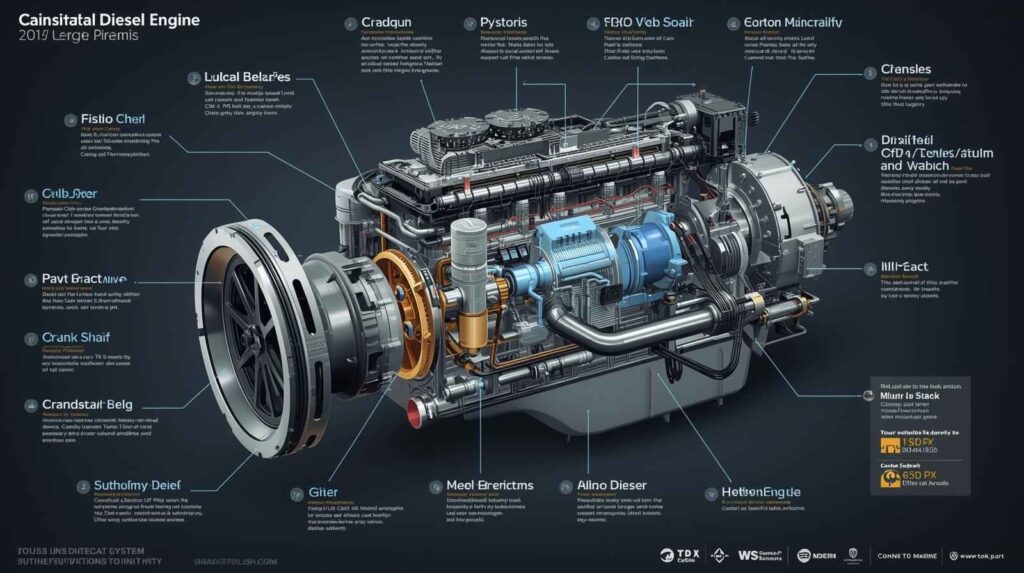

Every marine engine is a combination of several critical parts that work in unison to generate power. While designs vary across engine types, some components remain universal:

- Cylinder and Pistons: The heart of the engine, where fuel combustion occurs. Pistons move up and down inside cylinders to convert chemical energy into mechanical energy.

- Crankshaft: Connected to the pistons, it converts linear motion into rotational force, which eventually drives the ship’s propeller.

- Camshaft and Valves: These regulate the intake of air and fuel, and the exhaust of gases, ensuring proper timing for efficient combustion.

- Fuel System: Includes injectors, pumps, and filters that deliver fuel in precise amounts under high pressure.

- Cooling System: Since marine engines run for days without stopping, water-based cooling systems prevent overheating.

- Lubrication System: Supplies oil to reduce friction and wear on moving parts.

- Exhaust System: Channels waste gases out of the engine room while minimizing emissions.

Together, these systems keep the engine running smoothly, much like the organs of a living body.

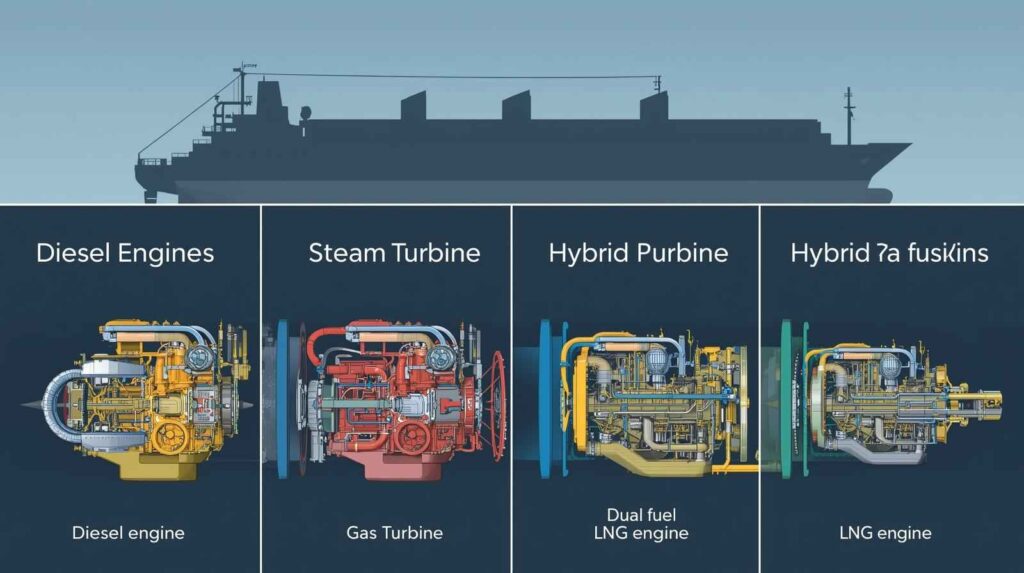

Types of Marine Engines

Marine engines can be classified into several categories based on fuel type, size, and function:

- Diesel Engines

- The most widely used in ships today.

- Favored for durability, fuel efficiency, and power output.

- Subdivided into two-stroke and four-stroke engines, depending on their combustion cycle.

- Steam Turbines

- Historically important, still used in specialized vessels.

- Runs on steam produced by boilers, making them less efficient compared to diesel.

- Gas Turbines

- Similar to jet engines, offering high speed and power.

- Common in naval ships due to quick start-up and light weight.

- Dual-Fuel and LNG Engines

- Use natural gas and oil alternately, offering reduced emissions.

- Increasingly adopted due to international regulations on marine pollution.

- Hybrid and Electric Propulsion

- Combine batteries and traditional engines for greener shipping.

- Still emerging but gaining traction with modern sustainability goals.

Each type has its pros and cons, but diesel engines remain the workhorses of global shipping.

How Marine Engines Work: A Simplified Look

At a fundamental level, marine engines operate on the same principle as most internal combustion engines: controlled explosions push pistons, which turn a crankshaft, ultimately spinning a propeller.

- Air Intake: Fresh air is drawn into the cylinder.

- Fuel Injection: Fuel is sprayed under high pressure, mixing with compressed air.

- Combustion: Ignition occurs, producing energy that forces the piston downward.

- Exhaust: Burned gases are expelled, preparing the cylinder for the next cycle.

Two-stroke marine engines complete this process in just two movements of the piston (up and down), while four-stroke engines need four. Two-stroke engines are more common in large ships because they produce higher torque at lower speeds, ideal for heavy loads.

Semantic and Linguistic Exploration of Marine Engine Technology

Understanding marine engine technology goes beyond mechanics, it also connects to the language and semantics around it, which helps broaden SEO value and conceptual clarity.

- Semantically Relevant Terms: combustion, propulsion, cylinder, crankshaft, torque, emissions.

- Lexical Terms: piston stroke, lubrication, turbocharging, bunker fuel.

- Hyponyms (subcategories): diesel engine, gas turbine, dual-fuel engine.

- Hypernyms (broader categories): machinery, propulsion systems, transport technology.

- Holonyms (whole systems): ship, vessel, engine room.

- Meronyms (parts of engines): piston, crankshaft, cylinder head, fuel injector.

- Synonyms: power plant, marine motor, propulsion unit.

- Antonyms: sail power, manual rowing, wind propulsion.

- Collocations: marine diesel, engine room, fuel efficiency, heavy fuel oil.

- Connotations: strength, endurance, reliability, sustainability.

- Etymology: “engine” originates from the Latin ingenium (meaning skill or cleverness).

- Polysemy: “engine” can refer to both a machine and a metaphor for driving force.

- Semantically Related Entities: IMO (International Maritime Organization), shipbuilders, marine engineers, fuel suppliers.

- Common Attributes: large, heavy-duty, reliable, continuous operation.

- Rare Attributes: vibration damping, cavitation resistance, thermal coating.

- Unique Attributes: designed for round-the-clock operation in corrosive saltwater environments.

By viewing marine engine technology through this lens, it becomes clear how deeply the concept ties into language, culture, and innovation beyond just mechanical engineering.

Applications of Marine Engine Technology

Marine engines power far more than just merchant ships. Their applications span across multiple industries:

- Commercial Shipping: Bulk carriers, container ships, oil tankers.

- Fishing Industry: Trawlers, longliners, and smaller boats.

- Tourism and Leisure: Cruise ships, yachts, ferries.

- Defense and Security: Naval destroyers, submarines, patrol boats.

- Offshore Operations: Oil rigs, research vessels, supply ships.

The adaptability of marine engines to different vessel types shows how versatile and indispensable they are.

Challenges and Misconceptions

Despite their importance, marine engines face challenges and common misconceptions:

- Misconception 1: Marine engines are just like car engines, only bigger.

- Reality: They’re built for endurance, not speed, and optimized for completely different conditions.

- Misconception 2: Marine engines are outdated compared to automotive technology.

- Reality: They’re continuously evolving, with advanced fuel systems and emission control technologies.

- Misconception 3: Marine engines don’t affect the environment much.

- Reality: Shipping emissions are significant, which is why regulations and new designs focus on sustainability.

Challenges include high fuel costs, maintenance requirements, environmental regulations, and the need for skilled labor to operate and maintain them.

Frequently Asked Questions

1. What is the most common type of marine engine today?

Diesel engines dominate due to their efficiency, durability, and power output, making them the preferred choice for most ships.

2. Why are two-stroke engines common in large ships?

Because they produce high torque at low speeds, which is ideal for pushing massive vessels over long distances.

3. Are marine engines environmentally friendly?

Not traditionally, but modern designs using LNG, hybrid systems, and scrubbers are reducing their environmental footprint.

4. What’s the difference between main propulsion and auxiliary engines?

Main propulsion engines drive the ship’s propeller, while auxiliary engines generate electricity for onboard systems.

5. How long can marine engines run without stopping?

With proper maintenance, they can run continuously for weeks or even months during long voyages.

6. What’s the future of marine engine technology?

Expect greater adoption of alternative fuels, hybrid propulsion, and stricter emission-compliance designs in the coming decades.

Conclusion and Final Thoughts

Marine engines may not get the same spotlight as automotive or aviation technology, but they quietly power the backbone of global trade and connectivity. From their humble beginnings with steam power to the advanced hybrid and dual-fuel systems of today, they’ve consistently evolved to meet human needs.

Understanding basic marine engine technology gives us more than just technical knowledge, it offers perspective on how interconnected our world is. Every package delivered, every cruise enjoyed, and every defense mission at sea depends on these machines working tirelessly beneath the decks.

Looking ahead, sustainability will shape the next chapter of marine engine development. Cleaner fuels, smarter engines, and hybrid designs are already paving the way toward greener oceans. The blend of tradition and innovation ensures that marine engines will continue to propel the world forward, both literally and figuratively.