Bag on Valve Technology: Redefining Modern Packaging Efficiency

Ever picked up a spray can and wondered how it delivers such a smooth, consistent mist until the very last drop? That’s not magic , it’s the quiet power of bag on valve technology (often shortened to BOV). This innovative packaging system has been changing the way industries think about aerosol delivery, hygiene, and sustainability. What was once just a niche technical solution is now becoming the standard in cosmetics, pharmaceuticals, and even food products.

When I first came across a BOV system during a product testing project, I was surprised by how simple yet effective it was. Imagine a flexible bag inside a can, separating the product from the propellant , it felt like packaging science had finally caught up with common sense. No mess, no contamination, and zero waste at the bottom. Over time, I’ve seen it turn from an engineering curiosity into a major leap in how brands promise “pure delivery.”

In this blog, we’ll dig deep into how bag on valve systems work, their benefits, and their growing role across industries. You’ll understand not just what makes this technology tick, but why it’s rapidly replacing traditional aerosol methods.

So, if you’ve ever wondered how your nasal spray, whipped cream, or sunscreen achieves that perfect spray consistency , stay with me. This technology has a story worth telling, and its future looks even brighter.

Understanding Bag on Valve Technology

At its core, bag on valve technology is a system where the product is sealed inside a flexible multilayer bag attached to a valve inside a pressurized can. The space between the can and the bag contains compressed air or nitrogen (the propellant). When you press the actuator, the pressure pushes the product out of the bag through the valve , without ever mixing with the propellant.

This simple separation makes a world of difference. It ensures the product remains uncontaminated, maintains shelf stability, and is dispensed evenly until the last drop. It’s essentially a combination of aerosol science and smart barrier packaging , clean, efficient, and reliable.

The Science and Structure Behind BOV Systems

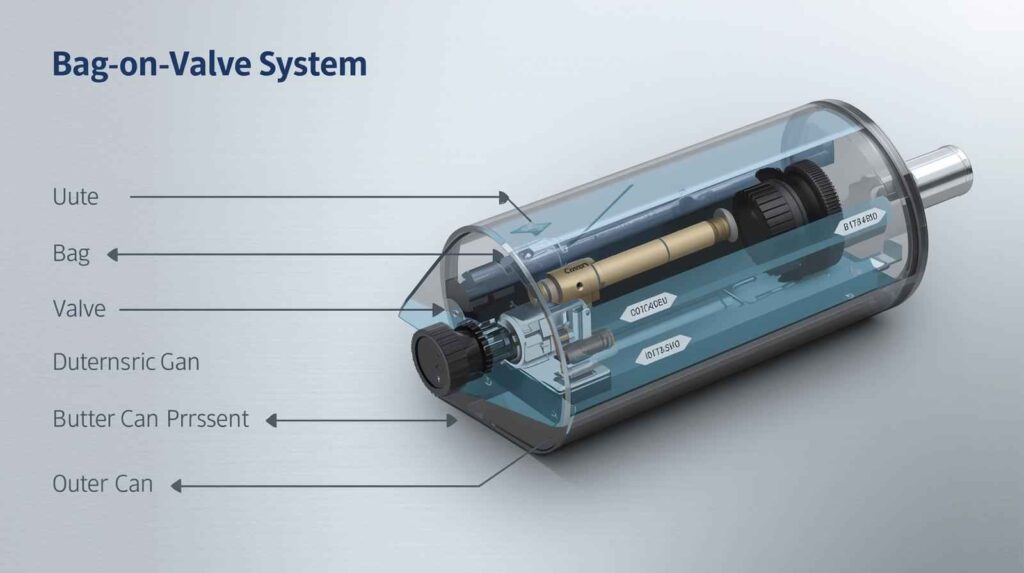

Let’s break down the system components:

- Can: Usually aluminum or tinplate, designed to withstand internal pressure.

- Bag: Made from laminated materials (like PET, aluminum, or nylon) to maintain product integrity.

- Valve and Actuator: Control the flow rate and spray pattern.

- Propellant Chamber: Filled with compressed air or nitrogen to create consistent pressure.

When the actuator is pressed, the pressure in the can forces the product out through the valve , all while keeping the propellant completely separate. Unlike conventional aerosols (where product and gas mix), BOV maintains a strict division that ensures clean dispensing.

This engineering design results in several advantages: a controlled flow rate, the ability to spray in any direction, and reduced product oxidation.

The Linguistic and Conceptual Aspects

From a linguistic and conceptual perspective, bag on valve technology can be understood through several semantic and functional layers:

- Semantically Relevant Terms: aerosol systems, pressurized packaging, air-powered dispensing, barrier packaging, and propellant separation.

- Lexical Terms: valve, canister, nozzle, actuator, bag, pressure chamber.

- Hyponyms: nasal sprays, shaving foams, sunscreen mists, wound care sprays.

- Hypernyms: packaging technology, fluid dispensing systems.

- Holonyms: product containers, pressurized delivery units.

- Meronyms: valve stem, actuator button, bag laminate, propellant chamber.

This web of associations reflects how BOV fits into the broader category of modern, sustainable, and hygienic packaging solutions.

How Bag on Valve Differs from Traditional Aerosols

Traditional aerosol systems rely on mixing the propellant (often hydrocarbon gases) with the product. That approach has clear downsides , propellant contamination, limited compatibility with sensitive products, and environmental risks.

In contrast, BOV systems eliminate those concerns by separating the product and gas. The product remains pure, and the propellant (usually just compressed air or nitrogen) never interacts with it. This not only enhances shelf life but also makes it suitable for eco-friendly and non-flammable applications.

So, while traditional aerosols might still dominate low-cost markets, BOV is leading the charge in sectors demanding purity, safety, and sustainability.

Common and Rare Attributes of Bag on Valve Systems

Common Attributes:

- 100% product dispensing efficiency.

- Consistent spray performance.

- 360-degree usability.

- Compatibility with liquid, cream, and gel formulations.

Rare Attributes:

- Sterile filling for pharmaceutical-grade products.

- Oxygen-sensitive formula protection.

- Odorless propellant system.

Unique Attributes:

- Environmentally friendly, non-flammable, and fully recyclable.

- Ideal for “clean label” brands that promote purity and sustainability.

These attributes collectively make BOV packaging not just functional, but strategic. It supports brand positioning for companies marketing “safe,” “natural,” or “eco-friendly” products.

Practical Applications and Industry Use Cases

You’ll find bag on valve technology in a surprisingly wide range of industries.

1. Pharmaceuticals

Used in wound sprays, nasal decongestants, and antiseptics where contamination-free delivery is critical.

2. Cosmetics and Personal Care

Popular in sunscreens, lotions, and shaving foams for consistent texture and hygienic dispensing.

3. Food Products

Applied in whipped cream, edible oils, and flavor sprays , offering freshness and easy portion control.

4. Industrial Applications

Ideal for lubricants, adhesives, and cleaning agents that require controlled spray application.

The versatility of BOV packaging lies in its compatibility with sensitive formulations , something traditional aerosols often fail to handle safely.

Misconceptions and Misinterpretations

Let’s address a few myths about bag on valve technology:

Myth 1: “It’s just another type of aerosol.”

Not exactly. Traditional aerosols mix gas and product. BOV keeps them separate, meaning it’s technically not an aerosol in the chemical sense.

Myth 2: “BOV systems are too expensive.”

While initial production costs can be higher, the overall efficiency , no wasted product, safer handling, longer shelf life , often offsets the investment.

Myth 3: “It’s only for high-end brands.”

That was true once, but the technology is becoming mainstream as more manufacturers realize the long-term cost savings and environmental benefits.

Challenges and Considerations

Every innovation comes with hurdles. For bag on valve packaging, the main challenges include:

- Manufacturing complexity: Requires specialized filling equipment and expertise.

- Material compatibility: The inner bag must resist chemical interactions with the product.

- Initial cost: Slightly higher than conventional aerosols, which may discourage low-margin markets.

Despite these, the benefits far outweigh the drawbacks. Companies that invest early tend to build a strong advantage in product purity and sustainability.

Environmental and Sustainability Benefits

Bag on valve systems align perfectly with the global shift toward sustainability. Unlike aerosols using hydrocarbons, BOV relies on harmless compressed gases, reducing carbon footprint and eliminating volatile organic compounds (VOCs).

Additionally, aluminum cans are infinitely recyclable, and the absence of chemical propellants means fewer regulatory hurdles and safer disposal. In short, this technology supports both green manufacturing and responsible consumerism , two pillars shaping the next era of packaging innovation.

The Future of Bag on Valve Technology

Looking ahead, BOV packaging is expected to play a critical role in eco-innovation. Advancements in bio-based laminate materials, smart valves, and customizable spray systems will further expand its capabilities.

Emerging trends point to integration with smart sensors and AI-driven filling systems , technologies that monitor product usage, optimize pressure, and even connect to IoT packaging analytics. As sustainability regulations tighten, BOV systems will likely become the default standard for premium and pharmaceutical products.

Frequently Asked Questions

1. What exactly is bag on valve technology?

It’s a packaging system where the product is stored in a sealed bag inside a pressurized can. The propellant surrounds the bag but doesn’t touch the product, ensuring purity and consistent dispensing.

2. How is it different from a regular aerosol?

Traditional aerosols mix the product with propellant gases. In BOV systems, the two are completely separated , delivering a cleaner, safer, and more efficient result.

3. Is bag on valve packaging environmentally friendly?

Yes. It uses compressed air or nitrogen instead of harmful gases, producing no VOC emissions and allowing full recyclability of the can.

4. Can it be used for food or medicine?

Absolutely. The system is ideal for sensitive applications like nasal sprays, wound care, and food-grade products since it maintains sterility and prevents oxidation.

5. Why is BOV becoming more popular now?

As brands focus on sustainability and user safety, bag on valve systems offer both , cleaner packaging and a better user experience.

6. Is it cost-effective for manufacturers?

In the long run, yes. Although setup costs are higher, reduced waste, longer shelf life, and eco-compliance make it more economical overall.

conclusion

Bag on valve technology isn’t just a packaging innovation , it’s a shift in mindset. It represents the move from “convenient but wasteful” aerosols to efficient, sustainable, and consumer-friendly systems.

Personally, I find it fascinating how something so simple , a bag, a valve, and a bit of air , can redefine entire industries. It’s a perfect example of engineering serving both people and the planet.

As consumer expectations evolve and sustainability takes center stage, bag on valve packaging will continue to gain ground. From healthcare to personal care, from industrial to edible , this technology is quietly proving that sometimes, the smartest solutions are the simplest.