QSP Optical Technology Inc.: Shaping the Future of Precision Optics

When we talk about cutting-edge optics, few names capture attention like QSP Optical Technology Inc. This company stands at the crossroads of innovation, science, and engineering , pushing the limits of what light can do. Whether you’re holding a smartphone camera, looking through a telescope, or working with laser systems, chances are that technologies refined by companies like QSP Optical are quietly making everything sharper, faster, and more precise.

I first came across QSP Optical Technology while reading about advancements in laser optics for industrial manufacturing. The sheer level of precision they were achieving blew me away , lenses that could handle microscopic tolerances, coatings engineered to withstand extreme environments, and calibration systems that almost seemed futuristic. It made me realize how deeply optics influence industries we take for granted, from healthcare to aerospace.

In this blog, we’ll unpack what QSP Optical Technology Inc. is all about , their core strengths, technologies, industry applications, and why their approach to optics is redefining global standards. You’ll also gain insights into common misconceptions about optical technology, the challenges that come with such innovation, and where the future of optics might be headed.

If you’ve ever wondered how modern devices achieve such flawless accuracy , or what it takes to make light behave exactly as we need it to , you’re in for a fascinating deep dive.

Understanding QSP Optical Technology Inc.

At its heart, QSP Optical Technology Inc. is a precision optics company that designs, engineers, and manufactures high-performance optical components and systems. Their portfolio includes lenses, prisms, mirrors, filters, coatings, and complete optical assemblies used in diverse fields , from defense and aerospace to medical imaging and laser processing.

The company’s philosophy revolves around one core idea: optical precision drives technological progress. Every innovation they deliver is about enhancing how light is controlled, transmitted, and reflected. Their engineers blend physics, material science, and mechanical design to create optics that meet the world’s strictest accuracy standards.

This combination of technical rigor and creative problem-solving has positioned QSP Optical among the most trusted names in advanced photonics manufacturing.

The Science and Structure Behind QSP Optical’s Technology

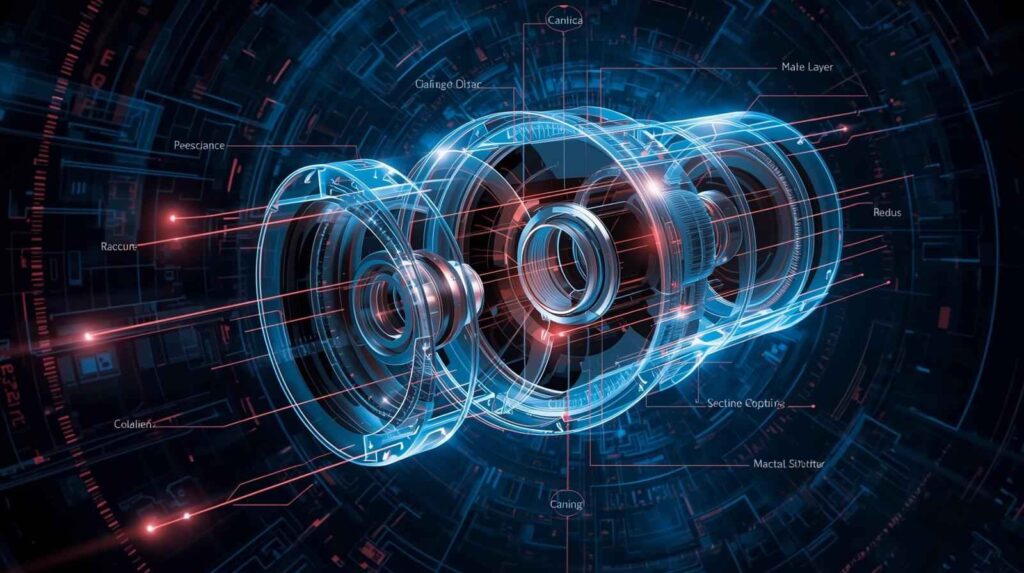

Behind every product lies a series of deeply interconnected processes , and in the optical industry, even the smallest miscalculation can result in massive performance gaps. QSP’s production pipeline integrates three key stages:

- Design and Simulation: Engineers use ray tracing, optical modeling, and advanced CAD software to predict how light behaves across each surface.

- Precision Fabrication: Using CNC polishing, diamond turning, and ion beam finishing, optical surfaces are crafted with sub-micron accuracy.

- Metrology and Testing: Every lens or mirror undergoes interferometric testing and surface profiling to ensure perfect conformity.

From single-element lenses to complex multi-lens systems, the company’s structure reflects a holistic understanding of optics , not just as components, but as systems of light behavior. This is where physics meets craftsmanship, producing optical elements that are as functional as they are beautiful.

The Linguistic and Conceptual Aspects of Optical Technology

When we analyze QSP Optical Technology Inc. semantically, several linguistic categories emerge that reflect its scientific and industrial essence:

- Semantically relevant terms: optical components, precision optics, photonics engineering, lens manufacturing, optical coating.

- Lexical terms: prism, lens, mirror, aperture, refractive index, optical axis.

- Hyponyms: aspheric lenses, UV filters, infrared mirrors, polarizers, diffraction gratings.

- Hypernyms: engineering, manufacturing, material science, photonics.

- Holonyms: optical systems, imaging devices, laser assemblies.

- Meronyms: coatings, substrates, mounts, surface layers.

- Synonyms: photonic innovation, optical engineering, precision light systems.

- Antonyms: optical distortion, misalignment, scattering loss.

- Collocations: optical coating process, lens polishing precision, mirror reflectivity, refractive design accuracy.

- Connotations: precision, clarity, innovation, scientific mastery, technological reliability.

Through these interconnected meanings, QSP’s brand represents not just a company but an ecosystem of light mastery , where language and science merge to symbolize human advancement through optics.

How QSP Optical Technology Differs from Traditional Optics Manufacturers

Many optics companies focus on producing components at scale. QSP Optical Technology takes a different route , they focus on integration and performance consistency. Rather than merely selling lenses or mirrors, they build complete optical systems designed to work flawlessly together.

Their approach combines:

- Customization: Each component can be tailored to specific wavelengths, environments, or tolerances.

- Vertical integration: Design, coating, testing, and assembly are all managed in-house, ensuring full quality control.

- Advanced coating technology: Multi-layer dielectric coatings provide durability and optimal transmission.

- Precision metrology: Every optical part is validated through interferometric testing and spectrophotometric analysis.

In simpler terms, QSP Optical doesn’t just make optics , they make precision possible. Their products aren’t off-the-shelf; they’re engineered solutions tailored for industries where accuracy defines success.

Common and Rare Attributes of QSP Optical Systems

Common Attributes:

- High transmission efficiency.

- Extremely low surface roughness.

- Thermal and environmental stability.

- ISO-certified quality assurance.

Rare Attributes:

- Dual-spectral coatings that function across visible and infrared bands.

- Proprietary optical polishing techniques that reduce scatter loss by over 40%.

- Smart metrology integration, combining digital feedback loops for real-time production correction.

Unique Attributes:

- Hybrid optical-mechanical systems optimized for next-generation applications like LiDAR and AI-based imaging.

- Deep R&D partnerships with universities and government laboratories.

Together, these traits make QSP Optical not just a supplier, but a strategic innovation partner for companies operating at the edge of technology.

Practical Applications and Industry Use Cases

QSP Optical’s technology finds its way into a remarkable range of applications. Some examples include:

- Aerospace and Defense:

Their optics are used in targeting systems, surveillance sensors, and satellite imaging. These systems rely on unmatched durability and zero aberration. - Medical Imaging:

From endoscopic lenses to laser surgery optics, QSP’s products support healthcare tools that demand pristine image clarity and safety. - Industrial Manufacturing:

In laser cutting, metrology, and material analysis, their precision optics enable micron-level measurement and process automation. - Consumer Electronics:

Smartphone cameras, AR headsets, and high-resolution displays often depend on miniature lenses and filters manufactured with QSP-like precision. - Scientific Research:

Universities and research centers use QSP’s optical components for experiments in quantum optics, spectroscopy, and laser physics.

In short, if light plays a role in a process, QSP Optical Technology probably has a footprint there.

Misconceptions and Misinterpretations

There are a few common myths about companies like QSP Optical Technology Inc., and it’s worth clearing them up:

Myth 1: Optical precision only matters for expensive equipment.

Reality: Even consumer-level products benefit from precision optics. The better the optical design, the more efficient and reliable the product becomes.

Myth 2: All optical manufacturers use similar technology.

Reality: The difference lies in tolerance levels, coating processes, and in-house testing , areas where QSP Optical excels.

Myth 3: Optical engineering is static technology.

Reality: Optics is constantly evolving, blending AI, automation, and nano-fabrication techniques to reach new performance levels.

By debunking these misconceptions, it becomes clear that optical engineering , and QSP’s role within it , is dynamic, future-focused, and vital to modern progress.

Challenges and Considerations

Every high-precision field faces obstacles, and optical manufacturing is no exception. QSP Optical Technology must navigate challenges such as:

- Material limitations: Certain optical substrates can be costly or difficult to polish.

- Thermal expansion issues: Even small temperature shifts can alter refractive properties.

- Supply chain precision: Global material sourcing must maintain consistent quality.

- Cost-to-performance balance: Maintaining affordability without compromising on tolerance accuracy.

Despite these, QSP’s in-house control systems and R&D-driven approach allow them to continually overcome these challenges, keeping them at the forefront of precision engineering.

Environmental and Sustainability Benefits

In a world moving toward greener technologies, QSP Optical has integrated sustainability into its operations. The company prioritizes:

- Waste reduction: Precision machining with recycling systems for glass and metal scrap.

- Non-toxic coatings: Use of environmentally safe deposition materials.

- Energy efficiency: Implementation of low-emission vacuum coating systems.

- Longevity: Designing optics that last longer, reducing product replacement cycles.

The environmental side of optics often goes unnoticed, but QSP’s sustainability-driven production model proves that performance and planet care can coexist.

The Future of QSP Optical Technology Inc.

The future of QSP Optical lies in integration, intelligence, and innovation. As industries demand more compact, smart, and multi-functional optical systems, QSP is already moving in that direction.

Emerging trends include:

- AI-assisted optical design to simulate and optimize performance.

- Nano-coating techniques that enhance light transmission and minimize reflection loss.

- Integration with IoT devices, enabling real-time feedback from optical systems.

- Miniaturization for wearable tech, autonomous vehicles, and biomedical devices.

QSP Optical’s forward-thinking mindset ensures they remain a leader in next-generation photonics. They’re not just adapting to change , they’re engineering it.

Frequently Asked Questions

1. What is QSP Optical Technology Inc.?

QSP Optical Technology Inc. is a company specializing in the design and manufacture of precision optical components and systems for industries like aerospace, healthcare, and photonics research.

2. What makes QSP Optical different from others?

They combine vertical integration, advanced coatings, and ultra-precise metrology to deliver products that meet the most demanding global standards.

3. Does QSP Optical produce custom components?

Yes. Their team works directly with clients to design optical systems customized to specific wavelengths, tolerances, and environmental conditions.

4. Which industries benefit most from their technology?

Aerospace, defense, medical imaging, industrial automation, consumer electronics, and scientific research.

5. Are their optics environmentally sustainable?

Absolutely. QSP employs eco-friendly coating methods and waste-reduction processes to minimize environmental impact.

6. What’s next for QSP Optical?

Expect breakthroughs in AI-driven optical design, smart sensor integration, and hybrid optical-electronic systems.

Conclusion

QSP Optical Technology Inc. isn’t just manufacturing components , it’s crafting the future of light-based innovation. Every lens, coating, and assembly they create brings us closer to technologies that see clearer, measure faster, and perform smarter.

What makes them truly stand out is not just precision, but purpose , a relentless commitment to advancing human capability through light.

As industries continue to evolve, QSP Optical’s blend of science, sustainability, and innovation ensures that its legacy will shine brighter than ever. In a world increasingly powered by photons, their mission is simple yet profound:

Make light work smarter , and make the world sharper.