Airgun Technology: Evolution, Innovation, and Modern Applications

Airgun technology has evolved from simple recreational shooting devices into sophisticated systems used for sports, training, and industrial applications. Once considered a niche tool for hobbyists, modern airguns now integrate advanced materials, precision engineering, and digital control systems that rival traditional firearms in accuracy and consistency.

The rise of airgun technology reflects broader trends in innovation , combining mechanics, pneumatics, and smart features to deliver power without combustion. These advances have made airguns safer, quieter, and more environmentally friendly.

As governments and manufacturers continue exploring cleaner shooting solutions, airguns have become central to conversations around sustainability and performance. Whether for target shooting, pest control, or defense training, they represent a balance between traditional ballistics and modern engineering.

Airgun technology uses compressed air or gas to fire projectiles instead of traditional gunpowder. By relying on pneumatic, CO₂, or pre-charged systems, modern airguns deliver consistent accuracy, smoother operation, and easier maintenance while staying quieter and more efficient than conventional firearms.

Understanding the Fundamentals of Airgun Technology

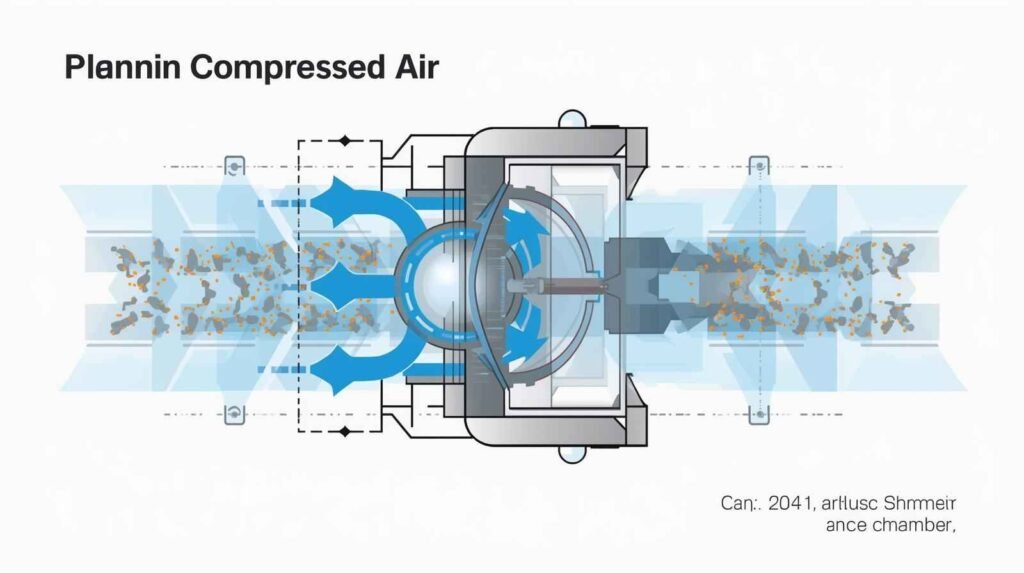

At its core, airgun technology operates on the principle of compressed air propulsion. Instead of explosive combustion, it uses stored energy within air or gas to propel a pellet through a barrel. This principle has made airguns both cleaner and more controllable than firearms.

There are three main types of airgun systems:

- Spring-Piston Airguns: Utilize a coiled spring that compresses air upon release. When the trigger is pulled, the spring drives a piston forward, creating air pressure that launches the projectile.

- CO₂ Airguns: Powered by small gas cartridges, these offer consistent firing and semi-automatic capability, making them popular for recreational shooters.

- Pre-Charged Pneumatic (PCP) Airguns: Store high-pressure air in built-in tanks and deliver superior accuracy, stable velocity, and minimal recoil , ideal for professional use.

Each system offers unique advantages in terms of precision, recoil, and ease of maintenance, allowing users to select based on application and preference.

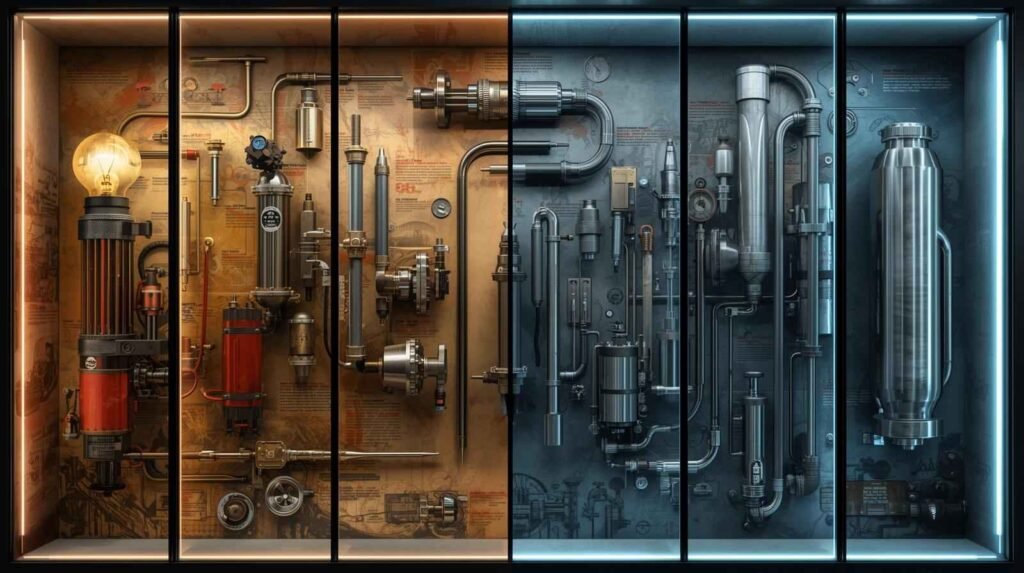

Historical Evolution of Airgun Technology

The history of airguns stretches back over five centuries. Early models, dating to the 1500s, were used for hunting and even military purposes. One of the most famous examples, the Girandoni air rifle developed in the late 1700s, could fire multiple shots silently , a remarkable advantage during its time.

By the 19th and 20th centuries, technological refinements such as better seals, improved barrels, and lightweight materials transformed airguns into reliable tools for sport and recreation. The post-World War II period saw the rise of CO₂-powered pistols and rifles, introducing modern convenience and power consistency.

Today, advancements in materials, digital monitoring, and manufacturing precision have taken airgun performance to new heights, solidifying their role across multiple fields from competitive shooting to industrial testing.

Key Components and Working Mechanism

An airgun’s effectiveness depends on the precise function of its components. Each part contributes to how efficiently the system stores and releases pressurized air.

- Air Reservoir or Cylinder: Holds compressed air or gas at high pressure.

- Valve System: Regulates airflow, controlling the projectile’s velocity.

- Barrel: Directs and stabilizes the projectile through rifling grooves.

- Trigger Mechanism: Releases stored air in a controlled burst.

- Stock and Scope: Provide structural support and aim precision.

When fired, the valve opens briefly, releasing a measured amount of compressed air. This propels the pellet through the barrel with consistent force. The balance of air pressure, barrel length, and projectile weight determines overall accuracy and kinetic energy.

Modern Innovations in Airgun Design

Technological innovation continues to reshape airgun design. Recent improvements focus on consistency, customization, and environmental efficiency.

a. Pressure Regulation Systems

Modern PCP airguns use built-in regulators to maintain uniform pressure per shot, ensuring minimal velocity variation and tighter shot groups.

b. Advanced Materials

Lightweight carbon-fiber air tanks and polymer stocks reduce weight while increasing durability.

c. Digital Integration

Some advanced models feature electronic triggers, pressure monitors, and digital shot counters that help users fine-tune performance.

d. Noise-Reduction Mechanisms

Integrated suppressors and baffle systems have made airguns significantly quieter, appealing to both professionals and recreational users.

These improvements make today’s airguns more precise, safer, and eco-conscious than ever before.

Applications of Airgun Technology

Airgun technology now serves multiple industries and user groups, far beyond traditional sports.

Sports and Competition

Airguns are standard equipment in Olympic and ISSF competitions, where precision and repeatability are critical. Their consistent velocity and low recoil provide a level playing field for athletes worldwide.

Pest Control and Hunting

Many farmers and pest management professionals use high-powered air rifles for humane pest removal. Their quiet operation reduces disturbance while maintaining accuracy and safety.

Training and Simulation

Law enforcement and defense agencies employ airguns for tactical training. These systems replicate firearm handling without the risks associated with live ammunition, making them ideal for safe marksmanship development.

Industrial and Research Applications

In laboratories and testing environments, air propulsion is used for mechanical impact studies, pneumatic system modeling, and pressure-based energy research.

Environmental and Safety Advantages

One of airgun technology’s strongest appeals lies in its environmental responsibility. Because there’s no combustion or explosive residue, airguns produce zero chemical emissions and significantly lower noise pollution.

They also offer enhanced safety features. Air pressure and velocity can be adjusted to match the user’s skill level or target requirements. Unlike traditional firearms, airguns carry minimal risk of accidental ignition or misfire.

Additionally, reusable air tanks and recyclable pellets contribute to a cleaner shooting experience, supporting both personal safety and ecological preservation.

Comparing Airguns and Firearms

Although airguns and firearms may appear similar at first glance, the way they function and perform is fundamentally different. Airguns rely on compressed air or gas to propel a projectile, while firearms use the combustion of gunpowder to create an explosive force. This difference not only affects power but also influences noise, maintenance, and overall handling.

Airguns are significantly quieter and easier to maintain since they produce no residue or heat from burning powder. Their operation is smoother and cleaner, making them ideal for controlled environments like training facilities, indoor ranges, and pest management. Firearms, on the other hand, generate higher recoil, louder discharge, and require frequent cleaning to prevent fouling.

From a legal standpoint, airguns are generally subject to fewer restrictions, allowing enthusiasts to practice shooting skills without complex licensing requirements. They are also far more affordable to operate , using refillable air tanks or CO₂ cartridges instead of costly ammunition. While firearms dominate in terms of long-range power and tactical use, airguns provide a practical, safe, and eco-friendly alternative for short to mid-range applications.

Overall, airgun technology represents a modern evolution in projectile systems , offering precision, economy, and environmental responsibility without compromising on performance or enjoyment.

Industry Growth and Technological Trends

The global airgun industry continues to expand rapidly due to innovations and shifting consumer demand.

Key trends include:

- Smart Integration: Incorporation of digital pressure gauges and Bluetooth connectivity for performance tracking.

- AI-Assisted Aiming: Algorithms that analyze environmental conditions to predict pellet trajectory.

- Customization: Modular designs allowing interchangeable barrels, regulators, and stocks.

- Sustainability: Transition to greener materials and refillable air systems to minimize waste.

Market analysts predict consistent growth in the next decade, driven by rising interest in recreational shooting and eco-friendly alternatives to gunpowder-based systems.

Limitations and Current Challenges

Despite clear progress, airgun technology faces several challenges:

- Limited Range: Airguns generally lack the extreme range of firearms due to lower projectile velocity.

- Dependence on Gas Supply: Frequent refilling can limit portability during long sessions.

- Weather Sensitivity: Temperature and humidity may influence pressure consistency.

- Public Misconceptions: Some underestimate the power or treat them as toys, leading to safety concerns.

Continuous education, stricter quality control, and user awareness campaigns are helping mitigate these issues worldwide.

Future Outlook for Airgun Technology

The next decade of airgun technology will be defined by smart features and sustainable design. Engineers are already exploring hybrid systems that merge pneumatic propulsion with electronic control.

Future developments may include:

- Self-regulating pressure algorithms for perfect consistency.

- AI-driven targeting assistance with real-time feedback.

- Wireless diagnostics through connected mobile apps.

- Eco-friendly ammunition and biodegradable materials.

These innovations will further refine accuracy, sustainability, and versatility, ensuring airguns remain vital tools in both recreational and professional domains.

Responsible Usage and Legal Considerations

Responsible ownership is key to safe airgun use. Although airguns are less regulated than firearms, proper handling is crucial.

- Always treat airguns as loaded.

- Never point at anything unintended.

- Use secure backstops in shooting ranges.

- Store and transport safely according to local laws.

Many countries require age restrictions or registration for high-powered air rifles. Adhering to these rules preserves safety and public trust.

Frequently Asked Questions (FAQs)

1. How does airgun technology differ from traditional firearms?

Airguns rely on compressed air or gas for propulsion, while firearms depend on explosive gunpowder. This makes airguns quieter, cleaner, and safer to operate.

2. What is the most advanced airgun system available?

Pre-Charged Pneumatic (PCP) systems lead the industry due to their superior pressure stability, adjustable power, and exceptional accuracy.

3. Can airguns be used for professional or defense training?

Yes. Many law enforcement and defense organizations use realistic airgun models for tactical training without live ammunition.

4. Are airguns regulated by law?

Regulations differ by country. While many regions allow recreational use, certain jurisdictions require permits for high-powered models.

5. How accurate are today’s airguns?

Modern PCP airguns can maintain pinpoint accuracy up to 100 meters, rivaling small-caliber rifles under controlled conditions.

6. What are the latest innovations in airgun technology?

Recent advancements include smart pressure gauges, AI-based aiming assistance, noise suppression systems, and sustainable materials.

Conclusion

Airgun technology stands as a prime example of mechanical evolution aligned with sustainability. From early pneumatic rifles to digitally enhanced precision systems, airguns have become versatile tools bridging the gap between recreation and innovation.

Their combination of safety, efficiency, and accuracy ensures continued relevance across sporting, industrial, and educational sectors. As new technologies emerge , from smart sensors to AI-powered controls , the airgun industry’s future looks stronger and cleaner than ever.

In essence, airgun technology is shaping the next generation of precision engineering, redefining performance standards while supporting an environmentally conscious approach to shooting and design.