SY Metal Technology Group: Innovation, Manufacturing Excellence, and the Future of Industrial Metal Solutions

SY Metal Technology Group is not just another name in the industrial metal sector. It represents a modern approach to metal manufacturing, one that blends engineering precision, scalable production, and practical innovation. In industries where quality tolerances are tight and performance expectations are unforgiving, companies like SY Metal Technology Group play a critical role in keeping supply chains reliable and efficient.

I’ve noticed that many people underestimate how much thought goes into industrial metal solutions. On the surface, metal products may look simple. In reality, they are the result of complex processes, material science decisions, and strict quality control systems. SY Metal Technology Group operates in this space with a clear focus on consistency, adaptability, and long-term value.

This article explores what SY Metal Technology Group is, how it operates, the technologies it relies on, and why it matters in today’s industrial landscape. You’ll also learn about its applications, strengths, challenges, and what the future holds for metal technology companies like this one.

Let’s start by understanding the foundation.

What Is SY Metal Technology Group?

SY Metal Technology Group is an industrial manufacturing company specializing in metal processing, fabrication, and technology-driven production solutions. Its core focus lies in delivering high-quality metal components and systems used across multiple industries, including construction, manufacturing, automotive, infrastructure, and heavy engineering.

At its heart, the company operates at the intersection of metal engineering and industrial technology. That means it doesn’t just produce metal products, it optimizes how those products are designed, manufactured, tested, and delivered.

The group typically works with materials such as steel, aluminum, alloys, and specialized metals, depending on application requirements. These materials are processed using advanced machinery, precision tooling, and controlled manufacturing environments to meet exact specifications.

The Role of Metal Technology in Modern Industry

Metal technology has evolved far beyond traditional foundries and manual fabrication. Today, it includes automation, digital modeling, material optimization, and quality analytics.

SY Metal Technology Group fits into this modern ecosystem by focusing on:

- Precision manufacturing

- Consistent material performance

- Scalable production capacity

- Process efficiency and waste reduction

Industries now demand metal solutions that are lighter, stronger, more durable, and easier to integrate into complex systems. This is where technology-driven metal companies stand apart from conventional suppliers.

Core Services and Capabilities of SY Metal Technology Group

SY Metal Technology Group’s operations typically revolve around a structured set of manufacturing and engineering services. These services are designed to support both standard production needs and custom industrial requirements.

Metal Fabrication and Processing

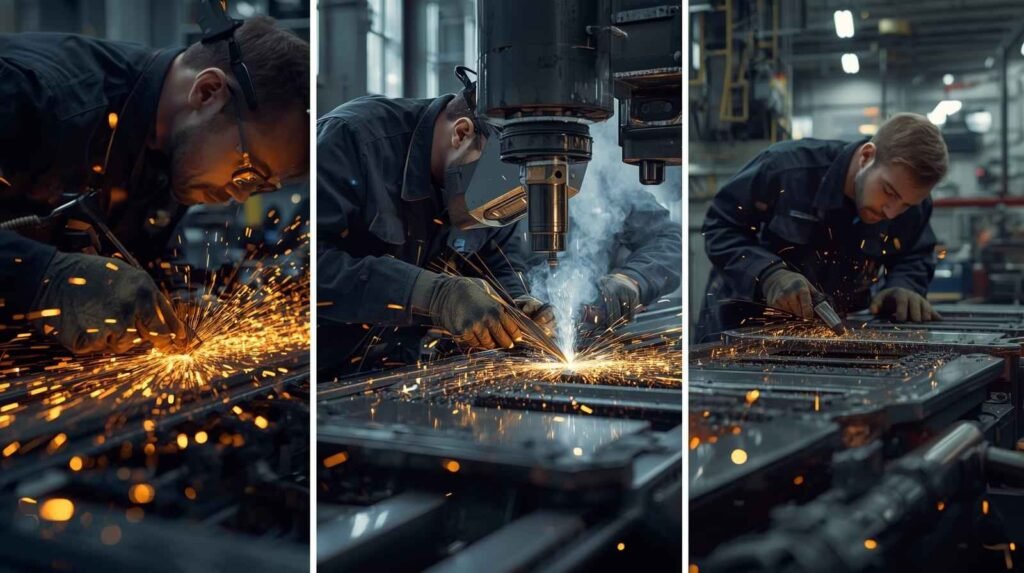

One of the group’s primary strengths lies in metal fabrication. This includes cutting, forming, machining, welding, and finishing metal components according to technical drawings and tolerances.

Fabrication processes are often supported by CNC machinery, laser cutting systems, and automated forming tools. This ensures repeatability and accuracy across large production volumes.

Advanced Manufacturing Techniques

Modern metal technology companies rely on advanced production techniques to remain competitive. SY Metal Technology Group integrates technology-assisted manufacturing methods that improve speed, reduce error rates, and maintain consistent output quality.

These techniques may include automated assembly lines, digitally monitored equipment, and real-time production tracking.

Quality Control and Testing

In industrial metal production, quality is not optional. Even small deviations can lead to equipment failure, safety risks, or compliance issues.

SY Metal Technology Group emphasizes structured quality control processes such as:

- Dimensional accuracy checks

- Material strength testing

- Surface and finish inspections

- Process consistency verification

This focus helps ensure products meet both client expectations and regulatory requirements.

Industries That Rely on SY Metal Technology Group

Metal technology companies rarely serve a single sector. Their value comes from versatility.

SY Metal Technology Group supports a wide range of industries where metal reliability is critical.

Construction and Infrastructure

Structural components, frameworks, and engineered metal parts are essential in construction projects. Precision and durability are key, especially for large-scale infrastructure.

Metal products supplied to this sector must handle load stress, environmental exposure, and long operational lifespans.

Manufacturing and Industrial Equipment

Factories and production facilities rely on metal components for machinery, tooling, and support systems. These components must perform under continuous use and high mechanical stress.

SY Metal Technology Group’s manufacturing capabilities allow it to meet these demanding conditions.

Automotive and Transportation

The automotive sector requires metal parts that balance strength with weight efficiency. Precision and consistency are critical, particularly for safety-related components.

Technology-driven metal production supports these requirements through controlled manufacturing and strict quality testing.

How SY Metal Technology Group Approaches Innovation

Innovation in metal technology is not always about radical change. Often, it’s about refining processes, improving efficiency, and reducing waste without compromising quality.

SY Metal Technology Group focuses on practical innovation, technology that improves real-world performance rather than chasing trends.

This includes:

- Process automation to reduce human error

- Material optimization for better strength-to-weight ratios

- Production planning systems to minimize delays

- Continuous improvement in fabrication techniques

These improvements may seem incremental, but over time they significantly enhance reliability and cost efficiency.

The Importance of Material Selection and Engineering

Material choice is one of the most critical decisions in metal manufacturing. Different applications demand different properties, strength, corrosion resistance, flexibility, or heat tolerance.

SY Metal Technology Group works within defined engineering parameters to select materials that match functional requirements rather than overengineering or under-engineering components.

This balanced approach helps clients avoid unnecessary costs while ensuring performance standards are met.

Supply Chain Reliability and Scalability

Industrial clients depend on reliable delivery schedules. Delays in metal components can disrupt entire production cycles.

SY Metal Technology Group emphasizes scalability and process planning to support both small batch production and large-volume orders. This flexibility is essential for industries with fluctuating demand.

Reliable sourcing, controlled inventory management, and production forecasting all play a role in maintaining supply chain stability.

Challenges in the Metal Technology Sector

Even advanced metal technology companies face ongoing challenges. SY Metal Technology Group operates in a competitive and resource-intensive industry.

Common challenges include:

- Fluctuating raw material prices

- Energy consumption and production costs

- Skilled labor availability

- Compliance with evolving safety and environmental standards

Addressing these challenges requires careful planning, technology investment, and operational discipline.

Sustainability and Responsible Manufacturing

Sustainability is becoming increasingly important in industrial manufacturing. Metal production can be resource-intensive, so efficiency and waste reduction matter.

SY Metal Technology Group focuses on responsible manufacturing practices such as:

- Minimizing material waste

- Optimizing energy usage

- Recycling metal byproducts where possible

- Improving production efficiency through automation

While sustainability goals vary by region and regulation, responsible practices also reduce long-term operational costs.

Common Misconceptions About Metal Technology Companies

There are several misconceptions surrounding industrial metal manufacturers.

One common belief is that metal technology is outdated or slow to adapt. In reality, companies like SY Metal Technology Group are increasingly data-driven and automation-focused.

Another misconception is that all metal products are interchangeable. In practice, material quality, processing methods, and tolerance control make a significant difference in performance and lifespan.

How to Evaluate a Metal Technology Partner

Choosing the right metal technology partner is critical for industrial success. When evaluating companies like SY Metal Technology Group, decision-makers should consider:

- Manufacturing capabilities and equipment

- Quality control standards

- Industry experience

- Scalability and lead times

- Communication and technical support

A reliable partner doesn’t just deliver parts, it contributes to overall operational stability.

The Future of SY Metal Technology Group and the Industry

The future of metal technology will be shaped by automation, data integration, and smarter material usage.

SY Metal Technology Group is positioned within a broader industry trend toward:

- Digitally controlled manufacturing systems

- Predictive maintenance and process monitoring

- Lightweight and high-performance materials

- Greater customization with shorter production cycles

As industries continue to demand precision and efficiency, metal technology companies that adapt will remain essential.

Frequently Asked Questions (FAQs)

What does SY Metal Technology Group specialize in?

SY Metal Technology Group specializes in industrial metal manufacturing, processing, and technology-driven fabrication solutions for multiple sectors.

Which industries commonly work with SY Metal Technology Group?

Construction, manufacturing, automotive, infrastructure, and industrial equipment sectors commonly rely on its metal solutions.

Is SY Metal Technology Group focused on custom or standard production?

It typically supports both standard production runs and customized manufacturing based on client specifications.

How does SY Metal Technology Group ensure product quality?

Quality is maintained through structured inspection processes, material testing, and controlled manufacturing systems.

What role does technology play in its operations?

Technology supports automation, precision machining, production monitoring, and efficiency optimization.

Is sustainability part of its manufacturing approach?

Yes, responsible material usage, waste reduction, and process efficiency are part of modern metal technology practices.

Conclusion

SY Metal Technology Group represents the modern face of industrial metal manufacturing. It combines engineering discipline, manufacturing technology, and operational reliability to meet the demands of today’s industries.

Metal may seem like a basic material, but the technology behind it is anything but simple. Companies that understand this, and invest accordingly, become long-term partners rather than just suppliers.

As industries continue to evolve, metal technology groups like SY Metal Technology Group will remain a foundational force behind infrastructure, manufacturing, and innovation worldwide.